The Madison-Rafah Sister City Project (MRSCP)

olive oil

Jul 16, 2025

May 3, 2025 Update: Palestine Solidarity Fair

Friends Meeting House, 1704 Roberts Ct, Madison, 2-4:30 pm Open House

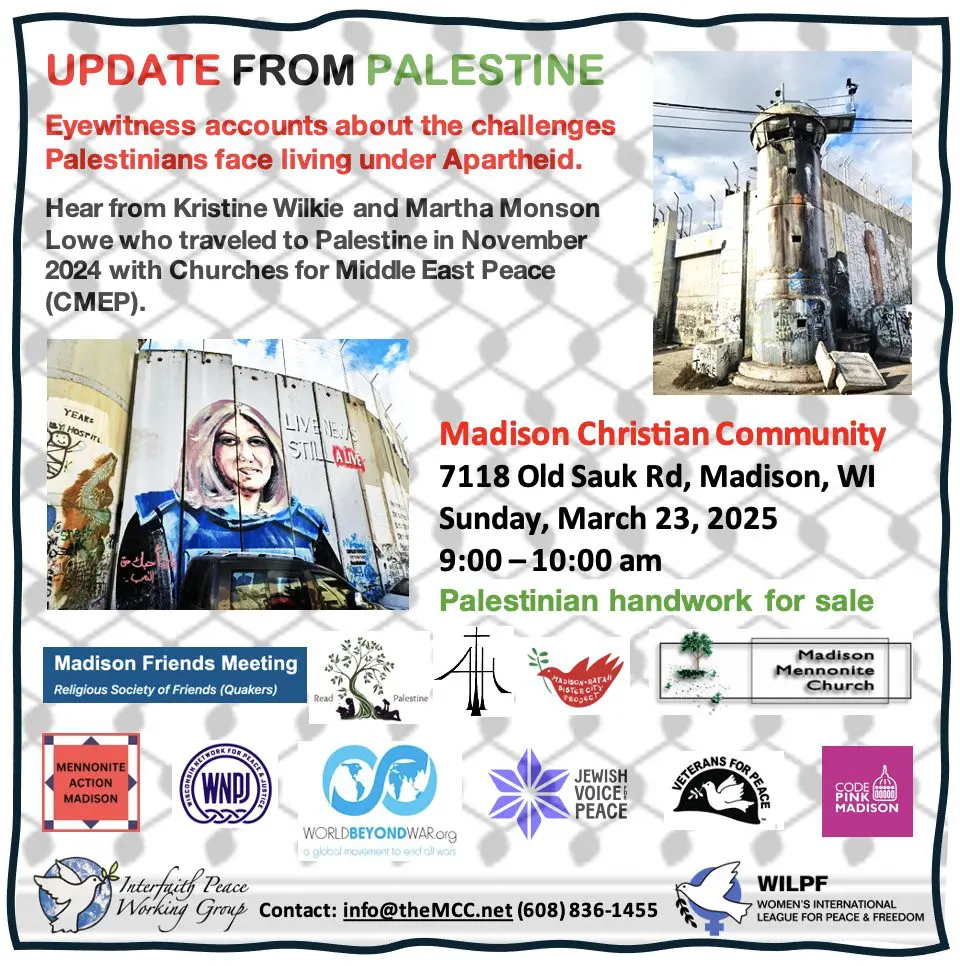

Mar 23, 2025: Update From Palestine

Madison Christian Community, 7118 Old Sauk Rd, 9:00 am

Mar 8, 2025: Overture Center International Festival

Madison, 10 am – 5 pm

Feb 23, 2025: Screening of “Burin Under Fire”

Online 12 PM CT

December 13: The War on Palestine and Lebanon and its Environmental Effects

Online 11 am CT On Rendering Uninhabitable: The War on Palestine and Lebanon and its Environmental…

Dec 15, 2024: Uprooting the Jewish National Fund

Online 1:30 pm CT Join the Green Olive Collective to discuss the central role of…

In Masafer Yatta There’s No P In PTSD

WORT 89.9FM Madison · In Masafer-Yatta there’s no P in PTSD WORLD VIEW, DECEMBER 8,…

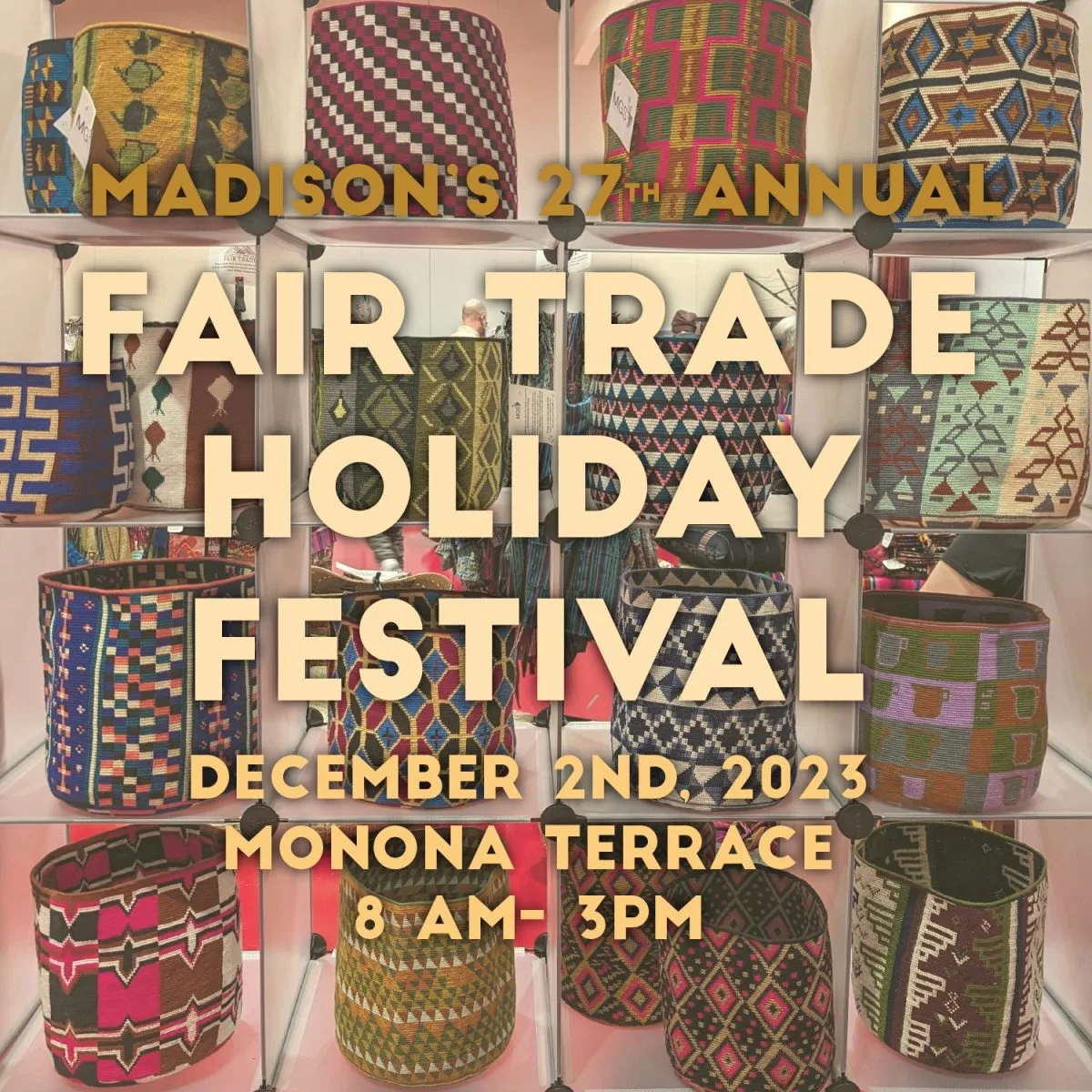

Dec 7, 2024: Fair Trade Holiday Festival

Monona Terrace8 am – 3 pm Madison’s 28th Annual Fair Trade Holiday Festival MRSCP, Palestine…

Olive Harvest 2024 will honor the resilience of Palestinian families

By Omar Waheed, Madison 365, Oct 15, 2024 A community event to highlight Palestinian resilience…

‘Destructive Impact’ – Israeli War Destroys 75% of Olive Trees in Gaza

Palestine Chronicle Staff, October 20, 2024 Palestinians in the besieged Gaza Strip were only able…

November 30, 2023

Live Event: Palestinian Olive Oil & Dates from the West BankShop now | Get Involved | Events Supporting Palestinian Farmers in the West Bank: Our…

Gaza’s olive harvest from farm to table

Widely regarded as the most blessed time of the year, Palestinian families in Gaza wait…

July 23, 2022

Madison-Rafah Palestinian Crafts Yard Sale318 W. Lakeside Street Madison [map] 10 am – 3 pm Mark your calendars… MRSCP…

June 4, 2022

Sidewalk Sale of Olive Oil, Crafts & Jewelry!1924 East Dayton Street, Madison (First Street between E. Washington and E. Johnson) 8:00 am…

Madison’s Virtual Fair Trade Holiday Festival is Open!

Our online store, Madison-Rafah Marketplace, has added crafts to our olive oil sales. We offer…

November 2020

Virtual Fair Trade Holiday FestivalDear Members and Friends of MRSCP, Mark your calendars for the upcoming Madison Fair Trade…

The Madison-Rafah Marketplace is Open!

In keeping with the times, we are now offering Palestinian Olive Oil and Donation and…

February 29, 2020

International FestivalOverture Center 201 State Street Madison 10 am – 5 pm Join MRSCP and many…

Mark Your Calendars: 2019 Fair Trade Holiday Festivals

November 24: 9 am – 2 pm Annual Fair Trade Sale at Orchard Ridge United…

July 24-25, 2019

Gaza Freedom Flotilla Comes to Madison!Photos: Jim Maas/FUS Social Justice Ministry, Tsela Barr/MRSCP, and Kit Kittredge/NA Boat to Gaza Campaign…

February 23, 2019

International Festival at Overture Center201 State Street Madison 10 am – 5 pm Once again Overture celebrates the rich…

March 3, 2019

Hashtag to Headlines: How the Gaza Great March of Return Challenged the WorldJoin us for the 2019 tribute to Rachel Corrie with Ahmed Abu Artema Writer,…

South Hebron Hills Update

Expulsion by a thousand cuts Dear Friends, The last weeks have been busy and challenging…

November 18, 2018

Orchard Ridge Holiday Fair Trade FairNovember 18, 2018 Orchard Ridge United Church of Christ 1501 Gilbert Road, Madison 9 am…

December 1, 2018

Monona Terrace Fair Trade Holiday FestivalMonona Terrace Convention Center 1 John Nolen Drive, Madison 8 am – 3 pm Come…

February 24, 2018:

International Festival at Overture CenterFree performances, food, and crafts from all over the world. MRSCP was selling our Palestinian…

December 2, 2017

Fair Trade Holiday FestivalMonona Terrace Convention Center 1 John Nolen Drive, Madison 9 am to 4 pm Come…

November 19, 2017

Orchard Ridge Fair Trade FairFeaturing beautiful and unusual holiday gifts and items from around the world. All proceeds go…

February 25, 2017

International FestivalOverture Center State Street, Madison 10 am – 5 pm Take a trip around the…

December 3, 2016

Madison’s Fair Trade Holiday FestivalGifts with a Story Monona Terrace Convention Center 1 John Nolen Drive, Madison 9 am…

November 20, 2016

Orchard Ridge UCC Fair Trade FairSunday, November 20 Orchard Ridge United Church of Christ 1501 Gilbert Rd, Madison [Map] Annual…

Update: April 3, 2016

Annual Rachel Corrie CommemorationSunday, April 3, 7 pm, Christ Presbyterian Church 944 East Gorham Street, Madison WI You…

Loving the Land and It’s People: Palestinian Hospitality

Veena Brekke, Madison-Rafah Sister City Project, October 31, 2012 On October 28th we departed the…

August 8 – 10, 2008

Rafah Soccer Tournament: Benefit Garage SaleShafia Powell and her friend Nabila have generously offered to host a garage sale next…

May 12, 2007

A Palestinian Crafts Extravaganza[pdf-embedder url=”http://madisonrafah.org/wp-content/uploads/2016/06/escape_party_flyer.pdf”]